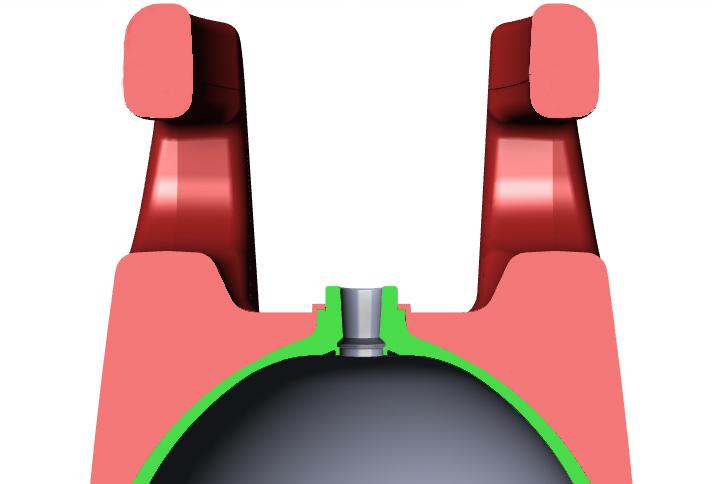

Cylinder with protection jacket

| Option I | Option II | |

|---|---|---|

| Hydraulic volume, L. | 10 | 20 |

| Dimentions, mm. | 288х288х527 | 338х338х632 |

| Working pressure, bar. | 300 | 300 |

| Pressure of destruction, bar. | 900 | 900 |

| Empty cylinder weight, kg. | 6,2 | 9,0 |

- More compact and 2,6 times lighter of best analog;

- Capability to implement automation filling, logistic robots and IoT integration.

Jacket design features

1

2

3

4

5

Marketing capabilities

1

2

VIPR with IoT and RFID option

- Know the pressure;

- Know the temperature;

- Gas volume monitor and orders planning;

- Cylinders geolocation and traffic management;

- Receive notification.

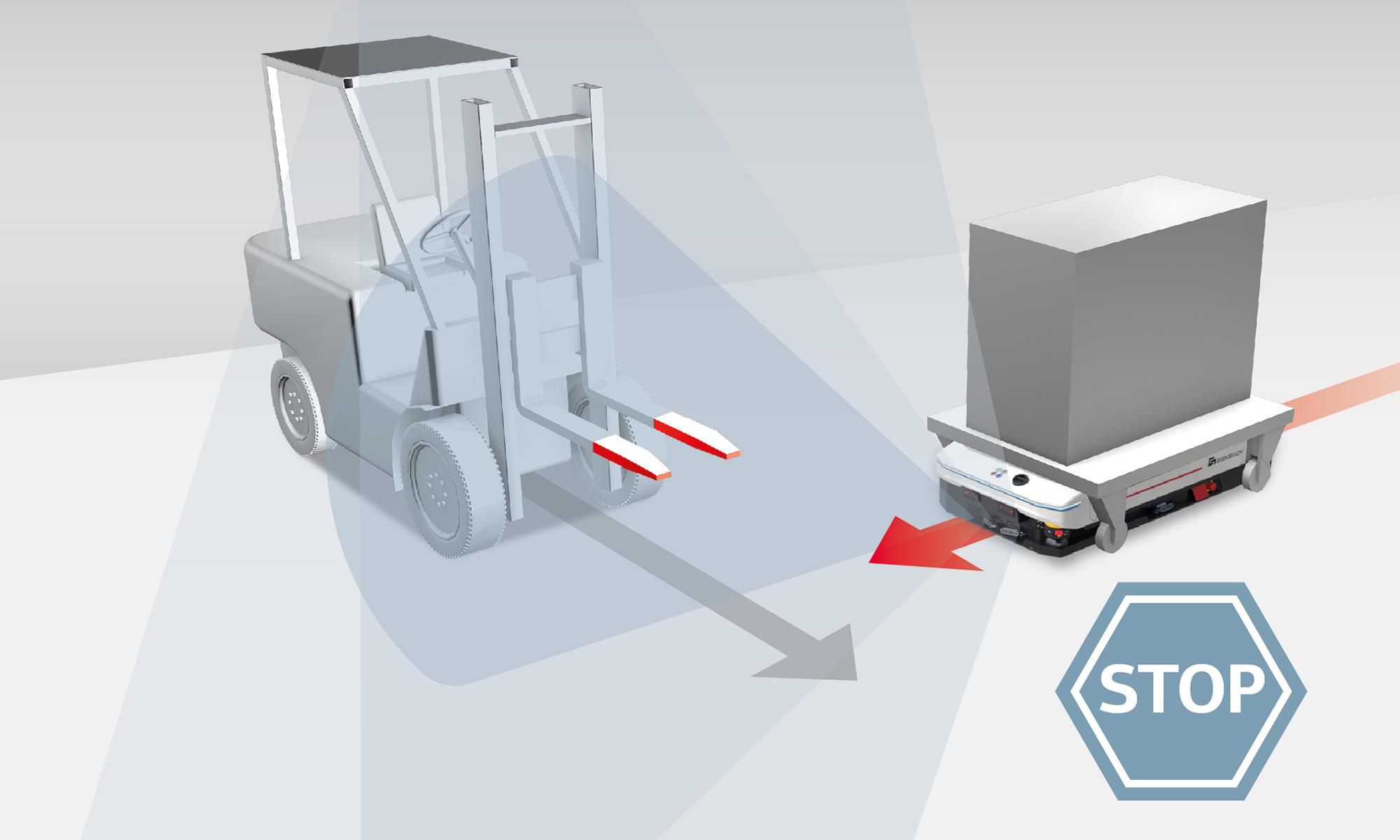

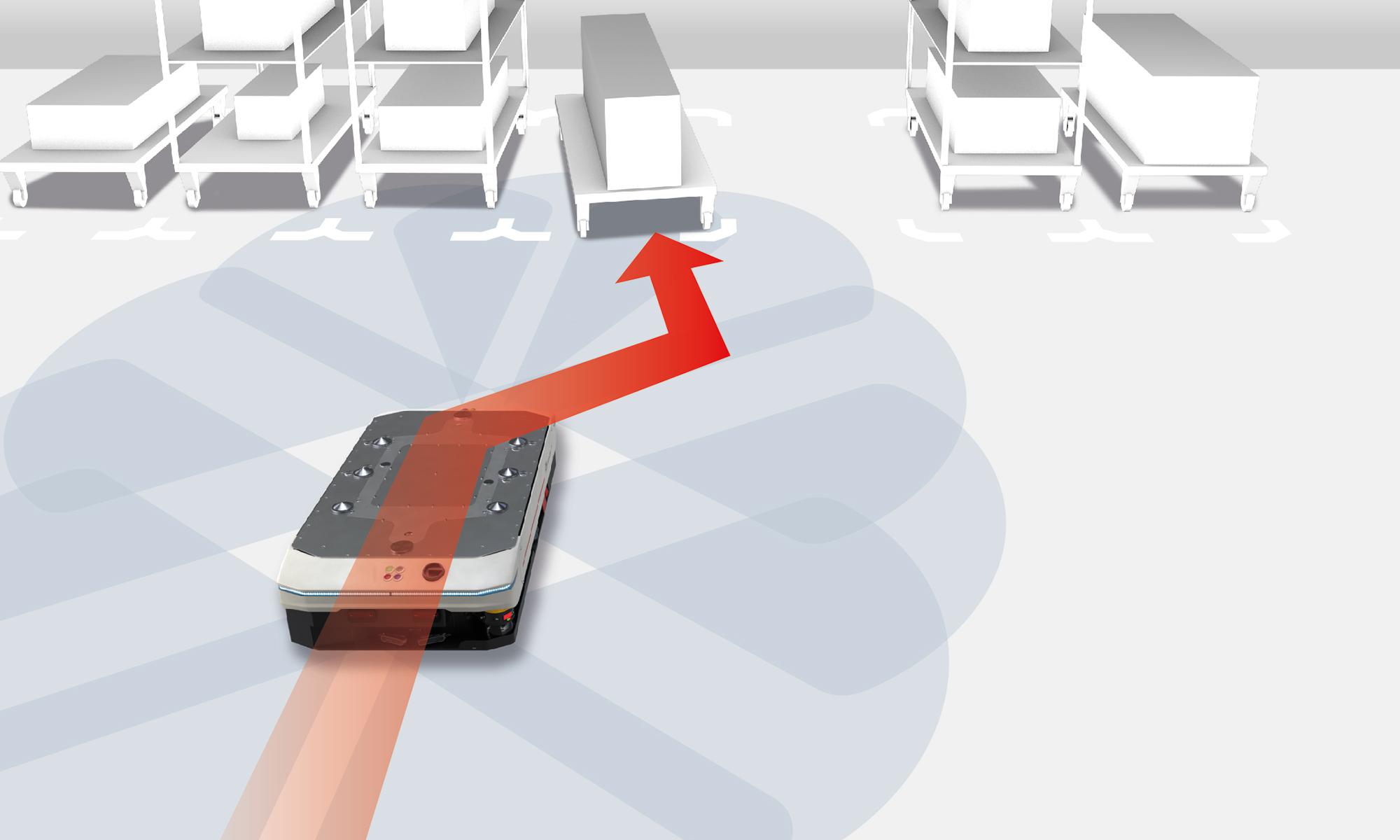

Robotization capabilities

IoT intagration

Traffic monitoring

Pathway optimization

- Logistic and filling operators labor costs essential savings;

- Additional income out of higher cylinders turnover rate (lower idle time);

- Logistic cots optimization by higher weight efficiency (higher gas volume with lower system weight);

- Lower construction and operation costs;

- Much higher safety programs efficiency and accidents loses reduction.

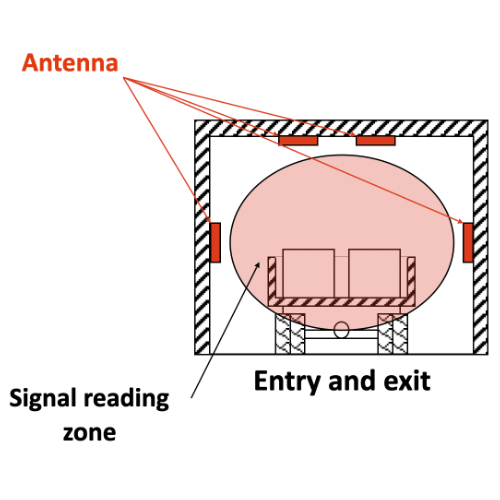

Remote reading system

- Counting the number of passed through cylinders and bundles;

- Shipped assortment and orders data;

- Sending a signal to the customer about upcoming delivery;

- Returned empty containers and unfulfilled orders data;

- Tasks generation for robots on returned cylinders distribution depends on their status;

- Weight control option is available.

Filling automatization capabilities

- Fully automated cylinders filling system;

- Cylinders size and purpose identification;

- Cylinders mechanical damages control and overall «ready to fill» check in;

- Capability to use adapters for different filling connection standards and pressure.